What is unified data management (UDM)?

Data sits at the core of modern business. When information enters an organisation from...

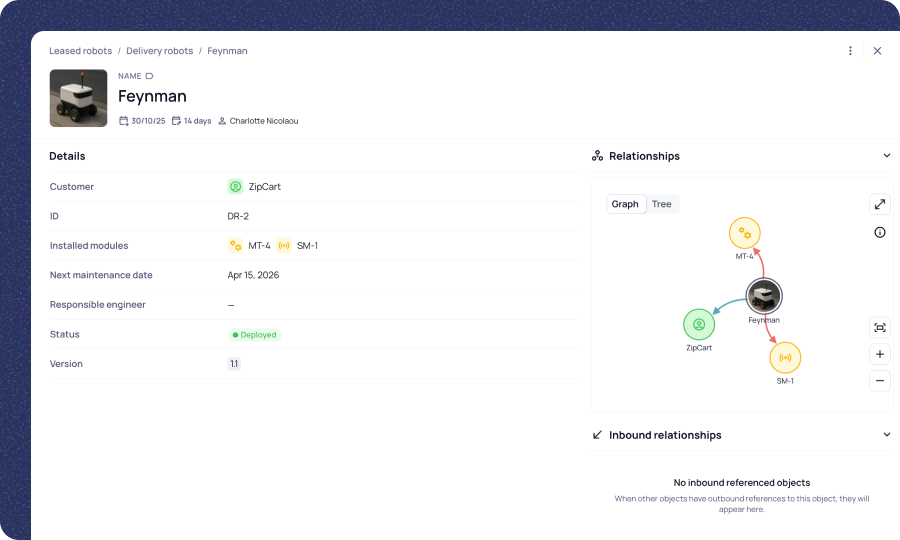

Understand uptime, configuration, maintenance, and customer for every robot you own. All from one workspace for every team.

Finding out where each robot is located, its current status, and which customer it's generating value for is a headache of spreadsheets and different systems.

The uptime of your robots directly impacts your profitability. But without accurate data on your robots, preventative maintenance is unrealistic.

Your robots are not isolated equipment. They have components and firmware installed, they're connected to customers and lease agreements. Without full context, decisions are harder to make.

Traditional tools can’t link different data together. Spreadsheets don’t know the difference between Robot #24 with gearbox A and Robot #24 after a camera upgrade.

Know every robot’s existence, setup, live position, customer, financial value, and more.

See how your robots are performing as a whole to maximise uptime and utilisation.

Track configuration, software versions, and modules (gearboxes, cameras, etc.). Spot issues with specific configurations early.

Automate service cycles and flag patterns and recurring issues (e.g., new drive module keeps failing).

Track your customers and contracts in the same tool as your robots, so your support team instantly gets the information they need to keep your customers happy.

Use this template for managing Robotis assets.

Build automations to locate and update your assets easily.

Remora Robotics develops autonomous underwater robots that clean and inspect fish farms. Their robots help aquaculture companies significantly improve fish health and reduce CO2 emissions, all while continuously checking the farm environments to flag potential issues before they become a problem.

They chose Starhive for their robots but started with managing IT equipment.

Industry: Robotics-as-a-Service / Aquaculture

Location: Stavanger, Norway

In Starhive, you decide which attributes to store to an asset. The asset can contain technical (gearbox type, firmware, sensors), operational, or financial data. Every change is logged and searchable for future reports.

Robots are expensive capital assets, and losing track of even one directly impacts profitability. RaaS companies also operate fleets across multiple customer sites, meaning uptime, maintenance cycles, and configuration changes must be monitored continuously. Traditional tools like spreadsheets can’t handle this complexity.

RaaS teams need a system that unifies financial data, operations, and technical configuration, a single place to see if robots are active, in storage, generating revenue, or at risk of failure

In Starhive, every component, a gearbox version, a camera model, a motor controller, can be stored as an object and linked to their parent robot. When a specific component starts causing issues, you filter the fleet by robots with that type of component and instantly see all affected robots.

This makes fleet-wide upgrades or recalls far easier and prevents repeated failures in the field.

Yes. Starhive was designed to support mixed asset environments from laptops and servers to robots, equipment, and manufacturing hardware. You can manage all IT, operational, and other business assets inside one workspace.

This is especially valuable for RaaS teams who rely on both digital infrastructure and physical robots to deliver their service.

Each robot automatically gets a unique, scannable QR code linked to its digital twin in Starhive. Field teams can scan the code to check status, log maintenance, upload photos or videos, and update information directly from a phone.

This removes the need to track maintenance notes manually and keeps all updates synced instantly across the company.

Starhive gives you real-time visibility into all robots across your operations:

Which units are active vs in stock

Live locations, or other sensor information

Yes. You can link each robot to its related engineering tasks, such as firmware updates, calibration work, or bug reports. That means R&D, field engineers, and operations all have a shared picture of what is happening with every robot in the field.

This reduces miscommunication and ensures that technical issues are tied directly to the right robot.

Absolutely. Starhive lets you set up automations to trigger maintenance based on:

Time intervals

Usage hours

Component versions

Uptime thresholds

Live data from sensors (coming soon)

You can assign tasks, send alerts, track upcoming service events, and record maintenance history. All of which is linked to the robot’s digital twin. Automated workflows ensure that servicing is never missed, even when your fleet grows.

Starhive allows you to create secure, customer-specific portals (Apps). Each customer can log in and see the robots they lease, including location, uptime, configuration, and service logs.

They can even submit requests for support or fault reports.

This creates transparency, reduces support load, and gives customers confidence in your service performance.

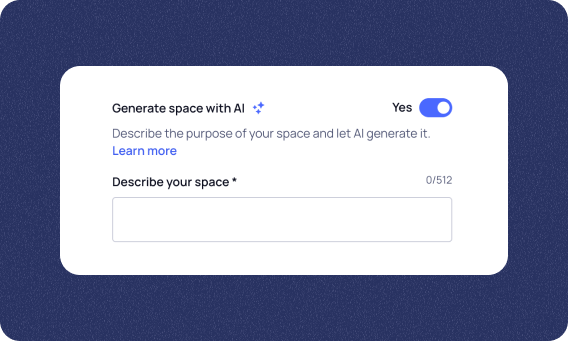

Describe the purpose of your space, and the AI will generate it instantly. Once your space is created, you can edit and tailor it further to your needs. All without writing a single line of code.

Data sits at the core of modern business. When information enters an organisation from...

Managing data efficiently is crucial for any organisation's success. Effectively managed...

Poor data can wreak havoc on any organisation, and the consequences are undeniably...

Your data is the lifeblood of your organisation. Think about it this way — you do...